Brake systems are one of the most critical components of vehicle safety. At the heart of these systems are brake discs. Brake disc manufacturers provide one of the most crucial elements of safe driving through advanced engineering, durable material selection, and continuous quality control processes. For vehicle owners, brake disc quality directly impacts not only performance but also safety.

What is a Brake Disc?

A brake disc is a metal part that rotates with the vehicle’s wheels and is compressed by the brake pads, reducing the vehicle’s speed or bringing it to a complete stop. Made of steel alloys or carbon-ceramic materials, these discs are designed to withstand high temperatures. Today, many manufacturers offer different brake disc models to suit different vehicle types.

Materials Used in Brake Disc Production

Cast iron is the most commonly used material in brake disc production. Its high-temperature resistance and cost-effectiveness make it a preferred choice for many vehicles. However, carbon-ceramic brake discs are used in sports cars, where performance and durability are paramount. Thanks to their lightweight construction, these discs enhance the vehicle’s acceleration and braking performance.

Brake Disc Types

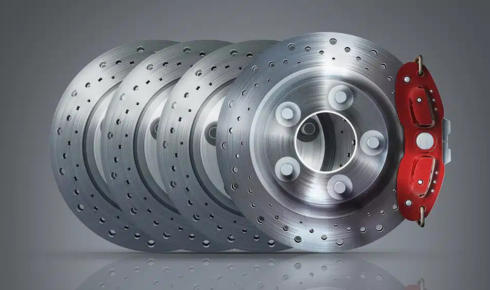

A brake disc manufacturer‘s product range varies to meet different needs:

· Solid brake discs: Typically used in small and mid-size vehicles.

· Drilled brake discs: Dissipate heat more quickly and are preferred in performance vehicles.

· Slotted brake discs: Increase the contact surface area with the brake pad, providing more powerful braking.

· Carbon-ceramic discs: Long-lasting and lightweight, they are found in higher-end vehicles.

How Long Does a Brake Disc Last?

The lifespan of a brake disc depends on driving habits, the intensity of use, and the quality of its manufacture. An average brake disc needs to be replaced every 50,000 to 80,000 kilometers. However, discs from high-quality manufacturers can extend this lifespan even further with regular maintenance.

What to Consider When Choosing Brake Discs?

Choosing brake discs is crucial for vehicle owners. The manufacturer’s reliability, material quality, and the vehicle’s technical specifications should be considered. Discs that meet original equipment manufacturer (OEM) standards are the best choice for both performance and safety.

Domestic Brake Disc Manufacturers

Turkey is a major production center in the automotive sector. Domestic brake disc manufacturers offer quality products to both the domestic and international markets. Thanks to advanced production technologies and quality control processes, they have reached a competitive level in the global market.

Brake Disc Prices

Brake disc prices vary depending on the brand, material, and production technology. While standard cast iron discs are more affordable, carbon-ceramic discs are more expensive. Vehicle owners are advised to choose based on quality and safety, not price.

Brake Disc Maintenance

Regular maintenance is essential for long-lasting brake disc life. Pad replacements should be done on time, brake disc surfaces should be cleaned, and disc thickness measurements should be checked regularly. Periodic inspections performed by professional service centers are crucial for driving safety.

Brake disc manufacturers produce one of the most important components of automotive safety. A quality brake disc not only ensures safe driving but also enhances vehicle performance. When choosing brake discs, vehicle owners should consider the manufacturer’s reliability, material quality, and compliance certification.